Jan 17,2024

Usage of wire harness comprehensive tester

1. Preparation work

Before starting to use the wiring harness comprehensive tester, make sure you have completed the following preparatory work:

Check equipment integrity: Ensure that all components of the tester are intact and undamaged, including cables, connectors, probes, etc.

Power supply and power cord: Ensure that the tester is connected to an appropriate power source and that the power cord is not damaged.

Environmental conditions: Ensure that the testing environment is clean and tidy, with no debris interfering with the testing process.

LEARN MORE +

Jan 17,2024

The low voltage resistance of the wiring harness comprehensive tester is insufficient

1. Wire quality issues

Low voltage resistance testing may be affected by wire quality. If there are problems such as poor welding, breakage, or substandard material quality in the manufacturing process of wires, it can lead to an increase in low-voltage resistance. At this point, visual inspection and testing of the wires are required to confirm if there are any issues. If there are any issues, the wires need to be remanufactured or replaced.

LEARN MORE +

Jan 17,2024

The principle of automatic machining of wire harnesses and its key role in the manufacturing of connecting wires

Automatic processing of wire harnesses is one of the important links in the connector industry, providing efficient, accurate, and reliable solutions for the manufacturing of connectors. In this article, I will provide you with a detailed introduction to the principle of automatic machining of wire harnesses and its key role in the manufacturing of connecting wires. What is wire harness automatic processing?

LEARN MORE +

Jan 17,2024

Wire harness structure: how to prevent crushing and correct fixing method

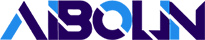

In the wiring industry, the design and installation of wiring harness structures are crucial. A wire harness is a comprehensive integration of connecting wires, including elements such as wires, cables, sleeves, etc., used for transmitting power, data, and signals. However, the wiring harness structure is easily affected by external environment and improper operation, leading to crushing and damage. In this article, we will discuss the reasons why wire harness structures are prone to crushing and introduce the correct fixing method to prevent such problems from occurring.

Why is the wiring harness structure prone to compression damage?

LEARN MORE +

Jan 17,2024

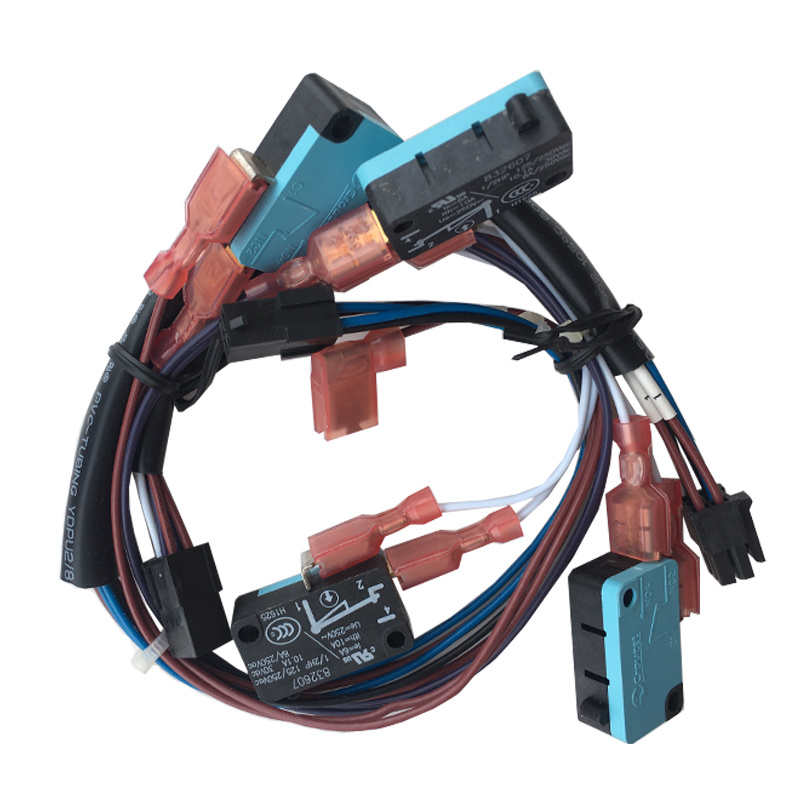

Details of the types and advantages and disadvantages of electronic wiring harness assembly wires

Electronic wiring harness is an important component in electronic products, composed of multiple wires, terminals, sheaths, etc., used for transmitting current or signals. Assembly wire is an important component of electronic wiring harnesses, which can be divided into copper core wire, aluminum core wire, enameled wire, shielded wire, flat wire, etc. according to different materials.

LEARN MORE +

Xiamen Aibolin Technology Co.,Ltd

No. 49. Meixi Road, Tongan, Xiamen, China

Give us an email to surprise you

Copyright © Xiamen Aibolin Technology Co.,Ltd All rights reserved.